As Indian manufacturing embraces the advancements of Industry 4.0, the focus shifts toward integrating intelligent systems that enhance efficiency, customization, and sustainability. Among these innovations, wedge wire screens emerge as pivotal components, aligning seamlessly with the objectives of modern, automated factories.

Understanding Industry 4.0 and Its Impact on Filtration

Industry 4.0 signifies the fusion of digital technologies with manufacturing processes, leading to smarter, more adaptable production environments. Key features include:

- Real-time Data Analytics: Enabling immediate decision-making and process optimization.

- Predictive Maintenance: Reducing downtime by anticipating equipment failures.

- Mass Customization: Allowing for tailored products without sacrificing efficiency.

In this context, filtration systems must evolve to meet the demands of precision, adaptability, and integration.

Wedge Wire Screens: The Smart Choice for Modern Filtration

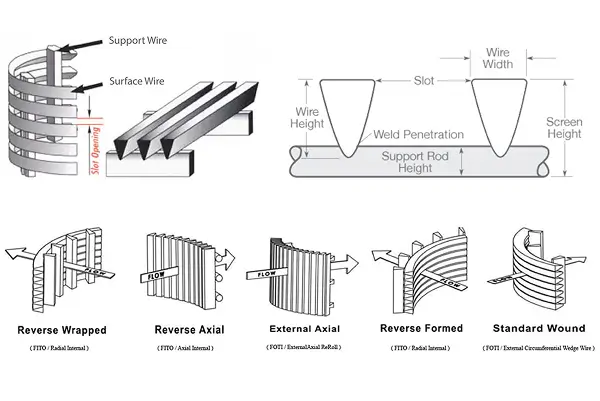

Wedge wire screens are engineered with precision, featuring V-shaped profiles that offer several advantages:

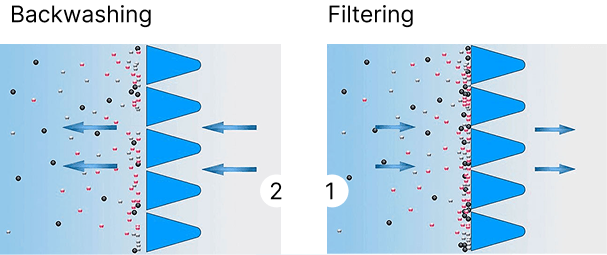

Enhanced Flow Rates: The design minimizes clogging, ensuring consistent filtration.

Durability: Constructed from robust materials like stainless steel, they withstand harsh industrial conditions.

Customizability: Slot sizes and configurations can be tailored to specific applications, aligning with the mass customization trend of Industry 4.0.

These attributes make wedge wire screens integral to smart manufacturing setups, where efficiency and adaptability are paramount.

Integration with Smart Factory Systems

Incorporating wedge wire screens into smart factories offers several benefits:

- Seamless Automation: Their consistent performance complements automated processes.

- Data-Driven Maintenance: Integration with sensors allows for monitoring and predictive maintenance, reducing unexpected downtimes.

- Energy Efficiency: Optimized flow reduces energy consumption, contributing to sustainability goals.

By aligning with the principles of Industry 4.0, wedge wire screens not only enhance filtration but also contribute to the overall intelligence of manufacturing systems.

Conclusion

As the manufacturing landscape evolves, embracing smart designs in every component becomes essential. Wedge wire screens exemplify this shift, offering precision, durability, and adaptability that align with the goals of Industry 4.0. By integrating such intelligent filtration solutions, factories can achieve higher efficiency, reduced downtime, and greater customization, positioning themselves at the forefront of modern manufacturing.