In the evolving landscape of industrial filtration, wedge wire screens have emerged as a superior solution, offering enhanced efficiency, durability, and versatility across various applications.

What Is a Wedge Wire Screen?

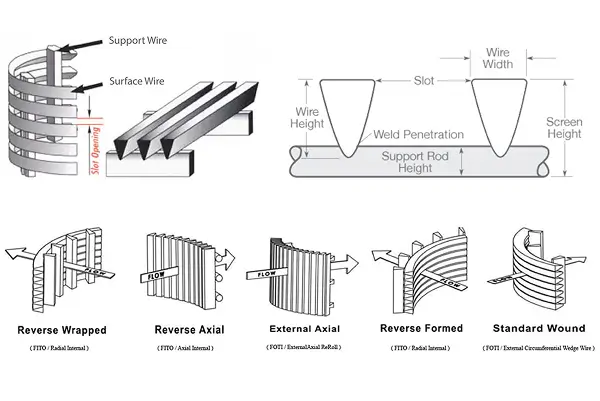

A wedge wire screen is a filtration device constructed by welding V-shaped (wedge) wires onto support rods. This design creates continuous slots that allow fluids to pass through while retaining solids. The unique structure ensures precise filtration and minimizes clogging.

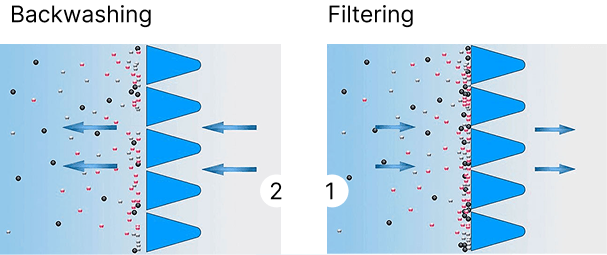

How Do Wedge Wire Screens Work?

Wedge wire screens operate on the principle of mechanical filtration. They are constructed by welding V-shaped (wedge) wires onto support rods, forming precise and uniform slots. As fluid or gas passes through these slots, solid particles larger than the slot size are retained on the screen’s surface, while smaller particles pass through. This design ensures efficient separation and minimises clogging.

Flow Directions:

Outside-to-In (Flow-Out-to-In): Fluid enters from the outside and exits from the inside. This configuration is common in applications where easy cleaning is essential.

Inside-to-Out (Flow-In-to-Out): Fluid enters from the inside and exits from the outside. This setup is often used when the collected solids need to be retained within the screen.

The choice between these configurations depends on the specific application and maintenance requirements.

Types of Filtration Achieved by Wedge Wire Screens

Wedge wire screens are versatile and can be tailored to various filtration needs across multiple industries:

1. Solid-Liquid Separation

Ideal for industries like wastewater treatment, food processing, and mining, wedge wire screens efficiently separate solids from liquids, ensuring cleaner effluent and improved product quality.

2. Size Classification

In mining and mineral processing, these screens classify particles based on size, aiding in the separation of valuable minerals from waste material.

3. Dewatering

Wedge wire screens are employed to remove excess water from solids, crucial in industries like pulp and paper, where moisture content affects product quality.

4. Pre-Filtration

Used as a preliminary filtration step, they protect downstream equipment by removing larger particles, extending the lifespan of finer filters.

5. Resin Trapping

In water treatment systems, wedge wire screens trap resin beads, preventing them from entering the distribution system and ensuring consistent water quality.

Each application benefits from the screen’s customizable slot sizes, high strength, and resistance to clogging, making wedge wire screens a reliable choice for diverse filtration needs.

Why Are They Revolutionising Filtration?

1. Precision Filtration

The uniform slots in wedge wire screens provide accurate separation of particles, making them ideal for applications requiring high precision.

2. High Strength and Durability

Constructed from stainless steel, these screens can withstand high pressures and are resistant to corrosion, ensuring a longer lifespan even in harsh environments.

3. Reduced Clogging

The V-shaped design minimizes clogging by allowing particles to pass through more easily, reducing maintenance needs and downtime.

4. Versatility Across Industries

Wedge wire screens are adaptable to various industrial applications, including water treatment, food processing, mining, and chemical processing.

Conclusion:

Wedge wire screens offer a blend of precision, durability, and versatility, making them an invaluable component in modern filtration systems. At Multitech Engineers, we specialise in providing high-quality wedge wire screens tailored to your specific needs.