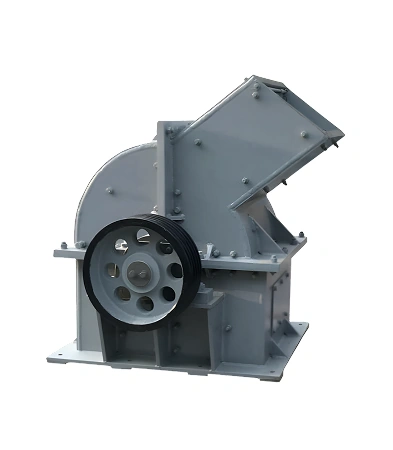

Material is fed into the crusher's chamber, where it encounters a rapidly rotating rotor equipped with hammers. These hammers impact the material, causing it to shatter against the breaker plates and internal walls. The crushed material then passes through a screen or grate, ensuring particles meet the desired size specifications. The design allows for efficient crushing with high throughput, and the adjustable settings enable precise control over output size.