How Wedge Wire Screens Support Circular Water Use is not just a technical topic. It is part of a bigger shift happening in factories, plants, and treatment systems across India.

Every month, we talk to engineers and EHS managers who say the same thing:

“We’re under pressure to reuse more water.”

“ZLD is now non-negotiable.”

“Our ESG audits are getting tighter.”

This isn’t just about compliance. It’s about survival.

Water is becoming expensive to use and harder to discharge.

And in that bigger system, small things matter.

Wedge wire screens are often overlooked. Because it plays quietly but plays a key role. They help save water, reduce waste, and protect the rest of your system.

This blog breaks it down.

No fluff. No tech jargon overload.

Just a plain explanation of where wedge wire screens fit, what they do, and how they help you move closer to zero discharge.

What Circular Water Use Means in Practice

What is Circular Water Use?

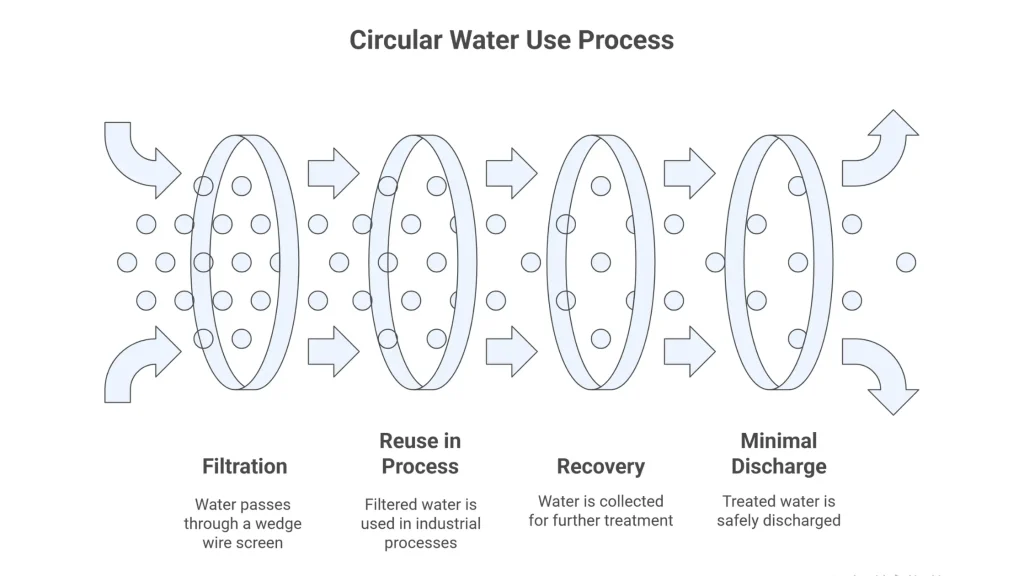

Circular water use is simple in theory: use water, treat it, reuse it again and again.

But in practice, it’s complicated.

You are dealing with dirty process water.

You have got oil, solids, fiber, starch, ash, grit. All depending on your industry.

You are trying to recover it, filter it, and reuse it without clogging the whole system.

Why Zero Liquid Discharge (ZLD)?

In many Indian states, especially in industries like textiles, pharma, sugar, or power, ZLD is now required.

It means you can not discharge anything. Not even treated water.

You need to recover, reuse, or evaporate every drop.

And this is where filtration becomes critical.

The better you remove solids early, the easier it is for RO, MEE, and evaporators to do their job.

Bad pre-filtration = more fouling, higher costs, shorter equipment life.

So while membranes and sand filters take care of the heavy stuff later, wedge wire screens quietly manage the flow from the very beginning.

How Wedge Wire Screens Support Circular Water Use

Wedge wire screens act like gatekeepers. They don’t just filter, they shape the entire water recovery process.

Efficient Solid-Liquid Separation

Think of a wedge wire screen like a sieve, but built for industrial punishment.

Slotted, stainless, and laser-welded – these screens can handle tough slurry, fibrous pulp, oily water, and fine particles without clogging.

In circular water systems, they are often the first line of defense.

When used ahead of sand filters, membranes, or evaporators, they reduce the solid load significantly.

This protects the rest of your system and saves energy.

Less Backwash, More Recovery

Traditional sand filters need frequent backwashing. That wastes water.

Wedge wire screens? Not so much. Their smooth surface and slotted design resist clogging.

That means less cleaning and fewer shutdowns.

One plant we worked with in the starch industry reduced their filter backwash water by 30% – just by switching to a properly sized static inclined hill screen.

They did not touch the rest of the system. Just changed the screen.

Simple upgrade. Big impact.

Longer Media Life

When you use wedge wire screens before media filters, you extend the life of the filter beds.

Fewer fines make it through. The pressure differential stays stable.

That’s less maintenance, fewer replacements, and better uptime.

Used Wedge Wire Screen, Such as.

- Static Incline Hill Screen

- Rotary Drum Screen

- Header & Lateral Systems

- Nozzles/Strainers

Wedge Wire Screens vs. Membranes and Sand Filters in ZLD Systems

In a ZLD system, everything works together. But not everything works equally.

Some components clog.

Some need chemicals.

Some are just expensive to maintain.

And then there are wedge wire screens. They work quietly but consistently.

Let’s look at how they stack up against membranes and sand filters.

| Feature | Sand Filters | Membranes (UF/RO) | Wedge Wire Screens |

|---|---|---|---|

| Clogging Risk | High | Medium | Low |

| Cleaning Needs | Frequent backwash | CIP with chemicals | Rare, easy rinse |

| Lifespan | 1–2 years | 2–4 years | 5–10+ years |

| Power Use | Moderate | High | None (gravity flow) |

| Role in ZLD | Secondary polishing | Final filtration | Pre-filtration / primary separation |

The real value of wedge wire screens shows up before trouble begins.

In a textile plant in Tamil Nadu, for example, membrane fouling was a daily issue. The team was using sand filters before their RO, but solids still got through.

We suggested installing a rotary drum screen ahead of the filter. Just that change cut membrane cleaning frequency by half in three weeks.

CPCB Direction and What Industries Are Doing Now

Regulations aren’t getting easier.

The CPCB has made it clear:

Industries must reduce water draw from natural sources and maximize reuse.

Many sectors are now expected to show zero discharge or near-zero discharge performance, especially if they operate in water-stressed zones.

Sugar mills, distilleries, and food processors are adding pre-filtration stages to cut down on effluent volume.

Wedge wire screens are becoming a default choice—not because they’re “new” but because they just work.

In some recent state pollution board audits, we have seen wedge wire-based filtration systems listed as part of best-practice setups. Especially in the first stages of ETPs and WTPs.

Related Products Used in These Plants:

📌 External reference:

See the National Water Mission guidelines for details on industrial water reuse, ZLD compliance, and water audit benchmarks set by the Indian government.

About Multitech Engineers

At Multitech Engineers, we have spent decades working with industries that cannot afford filtration failures. Our wedge wire screens, rotary drum screens, resin traps, and custom filtration components are built to support tough ZLD and water reuse demands. Without overcomplicating the process.

Whether you are upgrading a sugar mill’s primary filtration, setting up an ETP for a food plant, or redesigning pre-filtration before RO, we have seen what works. And more importantly, what lasts.

We don’t sell hype. We build solutions that work quietly in the background.

📌 Explore our full product range here.

Final Thought

Wedge wire screens are not showy. They won’t win awards.

But in circular water use systems, they pull more weight than they get credit for.

They:

- Stop solids at the source

- Reduce backwash and media replacement

- Protect costly downstream systems

- Work for years with minimal maintenance

That is why they belong in every serious ZLD plan.

How Wedge Wire Screens Support Circular Water Use is not just a technical detail.

It is a smart, low-risk move for any plant trying to stretch water, reduce discharge, and meet sustainability goals without spending a fortune.

If your filtration system keeps needing fixes, start at the start.

Check your screens.

✅ Ready to make your water system more efficient?

If you are working on ZLD goals or looking to reduce water loss in your filtration setup, wedge wire screens can help.

Get in touch with Multitech Engineers to discuss what fits your system best – no fluff, just practical solutions.