When it comes to industrial filtration, one solution rarely fits all. Industries like sugar processing, wastewater treatment, pulp and paper, and mineral separation require filtration systems. Customized to their unique material and flow demands. This is where the Wedge Wire Screen stands out —offering design flexibility that gives it a clear advantage over conventional filter types in optimizing operational efficiency.

At Multitech Engineers, we specialize in engineering wedge wire screens with precision — tailoring everything from slot size and wire profile to support rod configuration based on the unique requirements of your process. But why do these design parameters matter so much? And how do they impact performance, lifespan, and total cost of ownership?

In this blog, we’ll break down the core elements of screen customization:

- How slot size affects flow rate and separation efficiency

- The role of wire shape in clog resistance and structural strength

- How support rod spacing and orientation determine mechanical stability

- Real-world logic across key industries like sugar, starch, minerals, and wastewater

- Design examples and selection guidelines to help you make better choices

Whether you’re designing a new system or upgrading an existing one, understanding the science of screen customization can save you downtime, energy, and headaches in the long run.

Understanding Slot Size: The Gateway to Performance

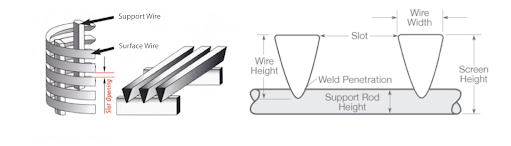

The slot size in a wedge wire screen is the width of the opening between two adjacent wedge wires. This dimension plays a pivotal role in defining what particles are retained or passed through, influencing separation efficiency, flow rate, and screen longevity.

Why Slot Size Matters

- Separation Efficiency: A smaller slot size can capture finer particles, which is essential in processes like tertiary wastewater treatment or starch extraction. However, undersizing can lead to clogging and reduced throughput.

- Flow Capacity: Larger slots offer higher flow capacity but lower filtration precision. Finding the right balance between flow rate and particle retention is key to screen optimization.

- Maintenance and Fouling: Incorrect slot sizing leads to frequent backwashing or manual cleaning—especially in slurry-heavy processes such as mineral dewatering or raw sugar juice screening.

| Industry | Application Area | Typical Slot Size (mm) |

|---|---|---|

| Sugar Processing | Juice screening, molasses filtration | 0.5 – 1.2 |

| Starch Processing | Fiber separation, slurry thickening | 0.3 – 0.7 |

| Minerals | Dewatering, ore separation | 0.2 – 1.0 |

| Pulp & Paper | Fiber recovery, water recycling | 0.15 – 0.6 |

| Water & Wastewater | Inlet screening, sludge treatment | 0.25 – 1.5 |

Profile Wire Shapes: Balancing Flow, Strength & Fouling Resistance

While slot size determines what passes through the screen, the profile wire shape influences how fluid interacts with the screen surface — directly impacting flow rate, clogging tendencies, and structural durability.

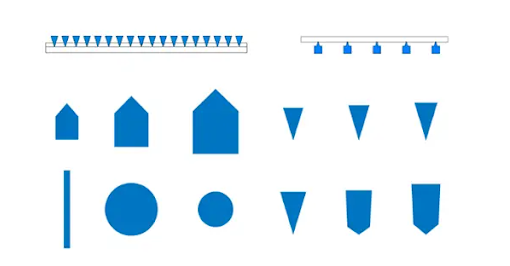

Wedge wire screens typically use triangular or trapezoidal-shaped wires, often referred to as “wedge” profiles. These aren’t just aesthetic decisions — they’re engineered for performance.

Common Profile Wire Shapes

| Profile Type | Description | Ideal For |

|---|---|---|

| V-shaped (Standard Wedge) | Narrower at the top, wider at the base | General filtration, self-cleaning |

| Trapezoidal | Flat top, wider base | High-pressure or structural loads |

| Round or Modified V | Semi-curved surface | Minimal turbulence, low-flow zones |

How Profile Shape Impacts Performance

- Self-Cleaning Effect: The V-shape naturally forces particles away from the screen, reducing blinding and fouling — especially helpful in pulp, starch, or raw wastewater flows.

- Open Area Optimization: A sharper profile provides greater open area per unit length, allowing more fluid to pass without compromising structural strength.

- Mechanical Load Distribution: Trapezoidal profiles offer better mechanical support in high-pressure or abrasive slurry environments.

- Debris Shedding: Round-top wires minimize buildup and are effective in low-turbulence zones but may have slightly reduced particle separation precision.

Matching Profile to Process

| Industry | Process Type | Recommended Wire Profile |

|---|---|---|

| Sugar & Starch | Sticky, fibrous slurries | Standard V-shape |

| Minerals | Abrasive, high-density | Trapezoidal or heavy-duty V |

| Pulp & Paper | Light fiber flows | V-shaped or round-top |

| Wastewater | Variable solids & pH | V-shaped or trapezoidal |

Wedge Wire Surface Profile & Support Profile Selection

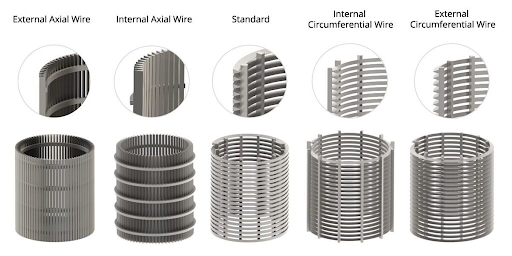

Support Rod Configuration & Screen Integrity

While slot size and wire shape control filtration behavior, the support rod configuration provides the essential backbone of a wedge wire screen. These rods — placed beneath the profile wires — bear the mechanical load, resist deformation, and maintain structural alignment under pressure.

The number, spacing, and orientation of support rods determine how well a screen can handle hydraulic load, vibration, and thermal expansion — especially in continuous-flow and abrasive conditions.

Types of Support Rod Configurations

| Configuration Type | Description | Best Used For |

|---|---|---|

| Horizontal (Parallel) | Rods run parallel to flow direction | Slurry dewatering, high-impact flows |

| Vertical (Perpendicular) | Rods run across the flow direction | Gravity-fed sieve bends, nozzles |

| Radial or Spiral | Curved orientation (in cylindrical drums) | Rotary screens, pressure vessels |

Design Considerations

-

-

- Rod Spacing: Tighter rod spacing increases strength and reduces deflection — essential for high-pressure or large-width panels.

- Rod Shape & Material: Support rods may be round, flat, or rectangular. Selection depends on screen size, mounting surface, temperature range, and chemical compatibility.

- Weld Integrity: The profile wire-to-support rod weld must withstand operational stress without cracking, especially under cyclic loading or thermal shock.

-

Customization Impact

A well-engineered support rod layout ensures:

-

-

- Higher mechanical stability under flow surges

- Reduced screen failure in vibrating or rotary machinery

- Longer service life in aggressive process environments

-

At Multitech, we configure every screen’s internal support structure based on your panel dimensions, application environment, and mechanical load profile, ensuring both reliability and manufacturability.

Designing for Your Industry: Sample Screen Layouts & Custom Engineering in Action

Every industry presents its own set of filtration challenges — from fibrous organic material to abrasive ore particles and variable pH effluents. That’s why custom-engineered wedge wire screens outperform off-the-shelf options in terms of performance, durability, and ROI.

Sample Layouts by Industry

| Industry | Slot Size (mm) | Wire Profile | Support Rods | Notes |

|---|---|---|---|---|

| Sugar | 0.7 – 1.2 | V-shape | Vertical (5–10 mm spacing) | High flow, fibrous juice, mild corrosion |

| Minerals | 0.3 – 1.0 | Trapezoidal | Horizontal (4–6 mm spacing) | High abrasion, requires hard welds or duplex steel |

| Pulp & Paper | 0.2 – 0.5 | Round or V-shape | Vertical (6–8 mm spacing) | Fiber-rich return water, self-cleaning preferred |

| Wastewater | 0.25 – 1.5 | V-shape or Trapezoidal | Vertical or Spiral | Varies by pH, solids load, and treatment flow |

| Starch | 0.3 – 0.6 | Sharp V-shape | Horizontal (5 mm spacing) | Sticky flows, prone to blinding |

Our Custom Engineering Workflow at Multitech

-

-

- Requirement Gathering: Application form + call with our technical team

- Process Parameter Review: Flow rate, solids load, pH, pressure

- CAD Design + Wire Selection: Based on filtration goal and screen dimensions

- Sample Visual + Quote: Includes a layout sketch and technical datasheet

- Manufacturing & QC: Fabricated in-house with post-weld inspection

- Dispatch & Technical Support: Documentation + maintenance advice included

-

When you work with Multitech, you’re not just buying a screen — you’re investing in a tailored filtration solution designed for maximum efficiency in your unique process environment.

Conclusion: The Power of Precision in Filtration

Customizing your wedge wire screen isn’t just about selecting components — it’s about engineering long-term reliability, efficiency, and cost savings into your filtration process.

From choosing the right slot size for your solids load, to picking a wire shape that enhances self-cleaning, to configuring support rods that handle real-world flow dynamics — every design decision adds value. These aren’t just technical tweaks — they are the difference between a screen that lasts 3 years and one that performs flawlessly for 8+ years.

At Multitech Engineers, we don’t just manufacture screens — we build solutions. Our in-house design team, advanced manufacturing setup, and process-specific expertise allow us to deliver screens tailored to your exact process requirements.

Ready to Customize Your Next Screen?

📞 Talk to our technical sales team to share your process parameters

🧪 Request a trial screen or consultation for your current application

🔗 Explore our manufacturing capabilities to see what sets us apart

Whether you’re building a new filtration line or retrofitting an existing unit, custom engineering is the key to better uptime, lower maintenance, and higher ROI.

Let’s build it better — together.