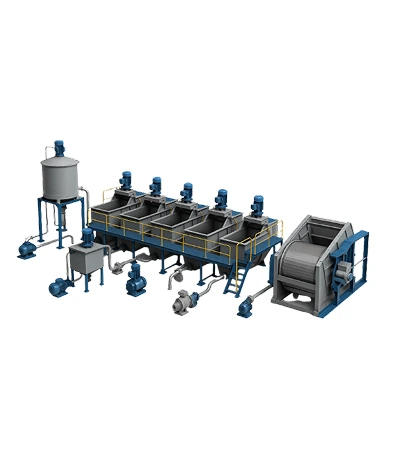

The froth product is skimmed, dewatered using the Rotary Vacuum Drum Filter, and discharged as clean, low-moisture coal. Wastewater is circulated back using tailing pond centrifugal pumps, while a magnetic pulley ensures removal of any tramp iron from the material flow. The fresh water and belt wash pumps ensure system cleanliness and stable operation.

Key Advantages

- Full-cycle slurry beneficiation in a modular design

- Optimized flotation efficiency using dual 4-cell battery configuration

- Integrated reagent dosing for maximum yield

- Low-moisture clean coal output via rotary vacuum filtration

- Closed-loop water handling with centrifugal recirculation

- Tramp iron removal via magnetic pulley ensures equipment protection

- Customizable layout for expansion and integration into existing plants