Modern manufacturing of wedge wire screens has changed how industries work with filtration and separation. We have moved from slow, inconsistent methods to precision-built screens made with speed and accuracy. For those who rely on these components – whether in water treatment, food processing, or chemical plants – this shift matters. Small changes in slot size or weld quality can affect your entire operation.

At Multitech Engineer, we have seen this change up close. We have built screens for companies that needed tight tolerances, fast delivery, and zero defects. And we have learned that when you automate right, you do not just make more – you make better.

This article explains how modern manufacturing works in our world. Not theory. Just the process, the impact, and why it helps you.

What Is Modern Manufacturing of Wedge Wire Screens?

Understanding the Process: Modern Manufacturing of Wedge Wire Screens

Think of wedge wire screens as the backbone of a filter. The way they are made decides how well they perform. In the past, it was mostly manual. Hand welding. Guesswork slotting. And often, inconsistent results.

Now things are different.

Modern manufacturing of wedge wire screens means using machines that can weld, align, and check with high accuracy. We use CNC-based systems to cut and slot wires. Automated TIG welding joins V-shaped wires to support rods, maintaining exact spacing throughout. Every screen is tracked. Every part is measured. We don’t just build parts – we follow a process built for precision.

Here is the simple difference: the old way depended on the skill of the worker. The modern way depends on systems designed for consistency. That’s how we meet slot sizes like 0.05 mm without variation.

It’s not about being fancy. It’s about being reliable.

When a pharmaceutical company asks us for screens with 0.1 mm tolerance and zero burrs, they know we can do it – not once, but every time. Because our process is set up that way.

How We Build It: Key Stages in Modern Manufacturing of Wedge Wire Screens

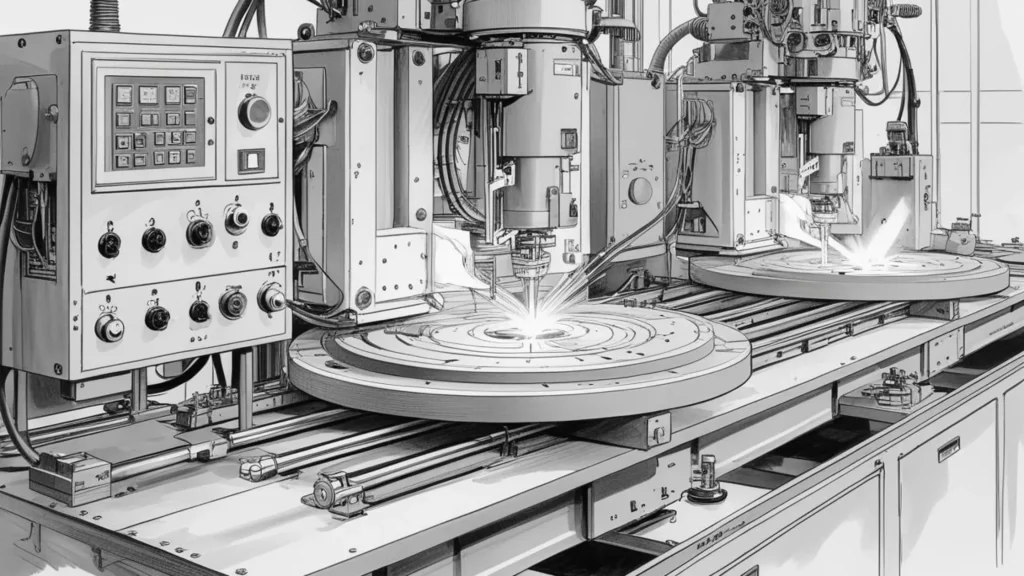

A. Automated Welding Systems

Welding is the heart of the screen.

In modern manufacturing of wedge wire screens, we do not rely on hand welding anymore. We use automated TIG welding systems. These machines weld V-shaped wires to support rods with tight control over heat, angle, and spacing.

This matters more than it sounds. When welds are not uniform, slot gaps shift. And when slot gaps shift, filtration becomes unpredictable. That is a big risk in critical industries like sugar, chemical, or wastewater treatment.

With automation, we maintain perfect wire positioning and fusion. No guesswork. No burnt edges. Just consistent welds.

We have seen clients switch from manually welded screens to ours and cut their maintenance calls in half. Less clogging. Better flow. More uptime.

And if a project demands different wire profiles or rod patterns, we reprogram the machine. No downtime. No trial-and-error. That’s what this stage is built for: control and repeatability.

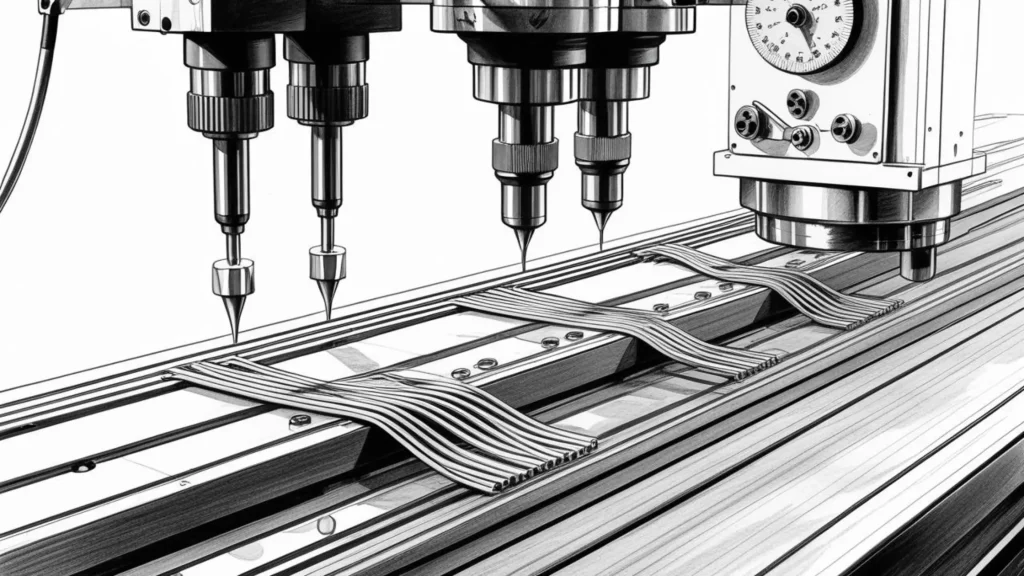

B. Slotting & Wire Alignment

This is where tolerances come into play.

In our plant, we do not “cut and hope.” Slot sizes are programmed into CNC-controlled systems. These machines cut slots to exactly what is needed. Whether that’s 0.05 mm for fine filtration or 3 mm for coarse flow.

Alignment matters too. Each wire has to sit exactly in line. Even a 0.1 mm shift can throw off performance.

We use digital micrometers, laser position sensors, and slot check gauges. And every screen is inspected before it moves to the next step.

If a client needs screens for resin traps or pressure vessels, we often include slot mapping reports. This way, they know exactly what they are getting. And they know it is within spec.

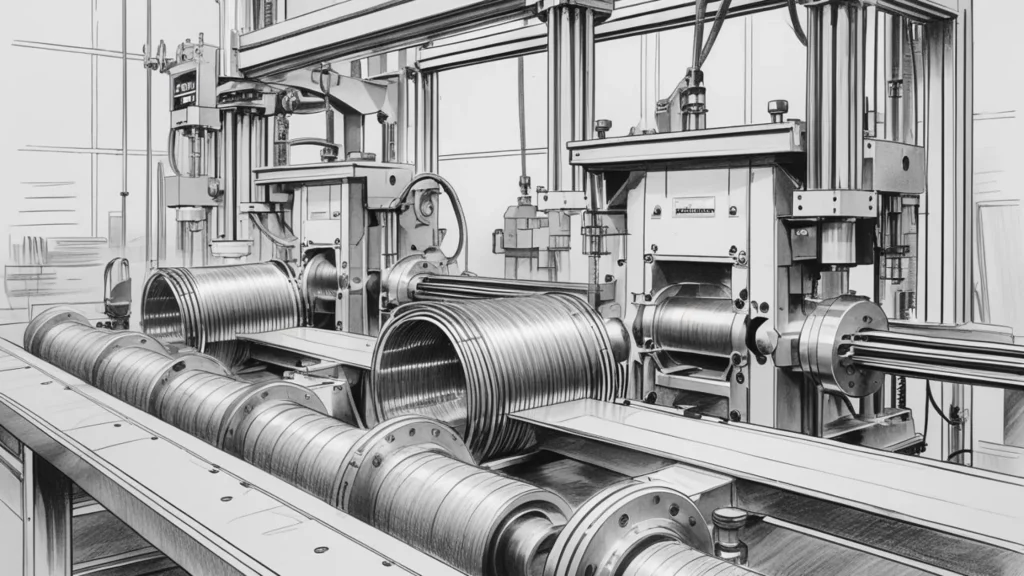

C. Framing and End-Fitting

Once the screen surface is welded and aligned, we frame it.

We do this in-house using automated ring rolling and forming machines. Whether it’s a centrifuge baskets, flat panel, or corn screen, we shape and weld it using jigs and rotary systems. That keeps form accuracy tight. Especially for curved applications.

End-fittings are then welded. These can be flanges, threads, caps, or couplings. Many customers send us their assembly specs, and we match them directly. No back-and-forth. No compatibility issues on-site.

Some clients only realize how precise this stage is when they try to replace a damaged screen from another vendor, and it doesn’t fit. That doesn’t happen with ours.

Because modern manufacturing of wedge wire screens is not just about producing. It’s about producing to spec, every time.

Why It Matters: Benefits of Modern Manufacturing of Wedge Wire Screens

When we talk about modern manufacturing of wedge wire screens, we are not just talking about using machines. We are talking about the real-world benefits that come from building screens. With better control, faster systems, and fewer errors. Here’s what that means for you.

A. Tighter Slot Tolerances

Slot size affects performance. A 0.2 mm spec that turns into 0.4 mm can lead to leakage or contamination.

We keep tolerances within ±0.02 mm using automated controls. Every screen is verified, and records are saved. You get what you ordered.

B. Faster Turnaround Time

All manufacturing happens in-house – no outsourcing. That is how we deliver standard screens in 5–7 days.

A mining client once received their order in 4 days, helping them avoid a shutdown. Fast delivery isn’t a promise. It’s normal.

C. Fewer Defects, Less Rework

Weld issues, misaligned wires, and poor frames lead to failures. We’ve reduced defect rates to under 1%.

Some clients have replaced 3-month screens from others with our 12-month performers—same job, better build.

That’s the difference modern manufacturing makes.

Inside Multitech’s In-House Manufacturing Ecosystem

At Multitech Engineer, we don’t outsource the hard parts. We do everything in-house – slotting, welding, rolling, framing, and testing. That’s how we keep control over quality, cost, and delivery.

This is not just about convenience. It is about responsibility. If something goes wrong, we do not blame a supplier. We fix it. But most times, we do not have to – because we built the system to prevent it.

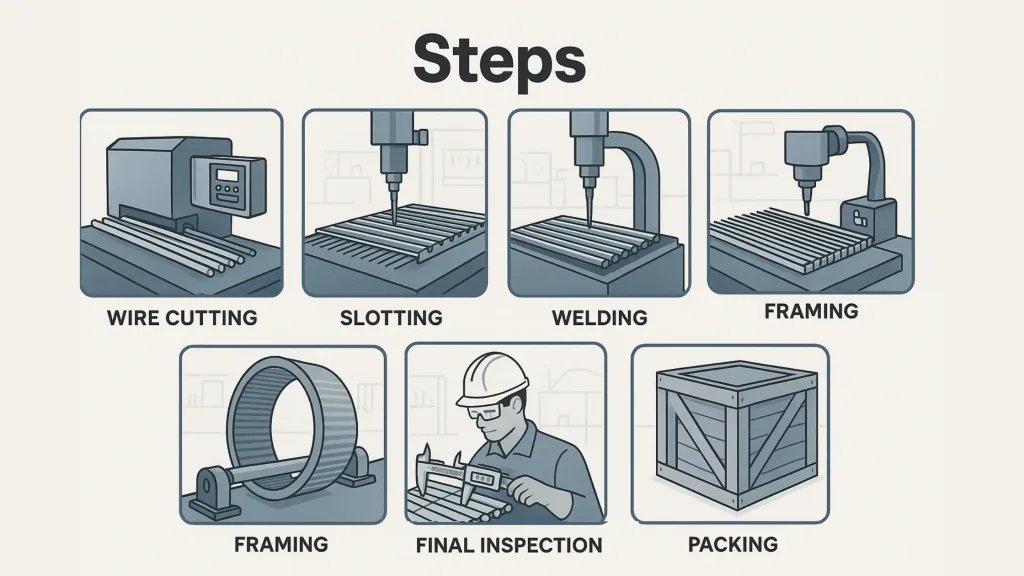

Our Full Process Under One Roof

When a job starts, it moves through clearly defined stages.

- Wire Preparation – We cut wedge wires and support rods to the required lengths using programmable cutting machines.

- Slotting – V-wires are slotted using CNC machines that set the spacing automatically. These are checked with micrometers and slot gauges.

- Welding – TIG welding is done on rotating jigs, controlled by PLCs. This keeps heat and alignment consistent from start to finish.

- Framing – Cylindrical, flat, or conical shapes are formed using ring rollers and bending fixtures. Ends are machined to match your specs.

- Inspection – Every screen goes through dimensional checks, slot width verification, and visual surface inspection.

- Packing and Dispatch – Once approved, we pack the screens in wooden boxes with clear tags and inspection sheets.

This flow is standard across most jobs unless the customer has special testing requirements like hydrostatic checks or PMI (Positive Material Identification). We do those too – on request.

Built for Custom Work, Not Just Standard Screens

Many of our orders are not off-the-shelf.

Pharma plants send us drawings for wedge wire nozzles with very specific threading. Pulp mills ask for screen baskets that match their old European machines. We handle all of it in-house using CAD/CAM tools and flexible welding setups.

That is where modern manufacturing of wedge wire screens gives us a real edge. We can adapt fast. We don’t need to wait for custom tooling or import anything. Our team can design, simulate, and build – all under one roof.

This gives potential buyers confidence that they are dealing with a real, structured operation, not a middleman or broker.

Our Product Range – Wedge Wire Screens Built for Real Use Cases

We do not make generic products. We build screens that solve problems. Whether it is media retention in a resin column or dewatering in a sugar plant. Our range covers most common industrial needs. But we also build custom assemblies for those who need something different.

Here is a quick look at what we make and where they are used.

Flat Panel Wedge Wire Screens

These are mostly used in static sieves and dewatering setups.

They offer consistent slot spacing and strong mechanical support.

Available in various sizes, thicknesses, and mounting styles.

Best for:

- Effluent treatment

- Food processing

- Mechanical screening

Centrifuge Baskets Wedge Wire Baskets

Also known as screen baskets, these are used when you need 360° filtration.

Made to fit rotary drum filters, and basket filters.

Customizable with flanges, handles, or shafts.

Best for:

Wedge Wire Nozzles

These are small but important. They are used in pressure vessels and filter beds for media retention and flow distribution.

We manufacture threaded, flanged, and custom-welded types.

Best for:

- Water softeners

- Ion exchange columns

- Resin filtration units

Hub and Header Laterals

These systems allow for even distribution or collection across filter beds.

Built by welding multiple nozzles or screen arms onto a central pipe.

We custom-design these as per vessel dimensions.

Best for:

- Pressure sand filters

- Activated carbon filters

- Demineralization units

Resin Trap Screens

Used as a safety device to catch escaping resin or media.

Made with fine slots and high strength to avoid system blockage.

Installed inline or inside tanks.

Best for:

- Water treatment

- Industrial process protection

- Power plants

Each product is manufactured using the same workflow we described earlier – slotting, welding, and framing – all under our roof. That’s how we keep every piece consistent, from a small nozzle to a large cylindrical screen.

And because we use the modern manufacturing of wedge wire screens, we can handle short runs, bulk quantities, or even one-off custom jobs, without losing quality or delaying delivery.

Conclusion:

Modern manufacturing of wedge wire screens is not a trend. It is a shift in how reliable components are built today. When tolerances are tight, delivery timelines matter, and systems can’t afford failure.

At Multitech Engineer, we have invested in automation not for the sake of technology, but because it helps you. It helps you get better products, faster. It helps reduce maintenance headaches. And it helps ensure that what you receive works exactly as expected – no surprises.

We don’t overpromise. We build what we say we will.

If you are looking for a supplier who understands your drawings. Sticks to delivery dates, and ships products that meet spec – reach out.

You can view our full product list here or contact us directly to request a quote.

We are ready when you are.