Introduction

Why Your Wedge Wire Screen Is Slowing Down Production is not just a question. It is a warning sign we see too often in the field.

Production rarely stops all at once. It slows. Quietly. One shift takes longer. One tank doesn’t clear fast enough. And suddenly, you are not hitting your numbers.

We have seen this in sugar mills running cane at full capacity. In starch plants dealing with thick slurry. In wastewater treatment units, processing peak loads. The machines seem fine. Pumps are running. Flow meters show movement. But something’s off.

In many cases, it is the screen.

It is not torn or broken. It is just working less than it should. Slot by slot, it clogs. Slowly, it chokes the system.

This blog is written for people who run those systems. For engineers, plant managers, and operators across sugar, starch, oil, wastewater, pulp, and chemical industries. If you are seeing slowdowns and do not know why, read on. We have seen it. Fixed it. And we will explain how.

Why Your Wedge Wire Screen Is Slowing Down Production

I remember a starch plant in central India. Their germ separation line was not keeping up. They replaced the valves. Cleaned the tanks. Checked the pump. Still slow.

It turned out to be a second grind screen that had run two weeks too long. The slot openings were partially blocked. The flow rate was down 20%. Once they swapped it with a fresh, correctly slotted unit, things snapped back to normal.

This happens more than you’d think.

Screens get ignored. They are hidden, quiet, and not usually blamed. But they can throttle your system just enough to hurt output – without setting off alarms.

In sugar factories, fiber wash screens often clog when the cane is muddy or overripe.

In wastewater plants, rotary drum screens slow down under higher solids load if the slot size isn’t matched right.

In paint or chemical processing, bead mill screens lose efficiency when cleaning cycles are skipped.

If your flow rate is down, or you are cleaning screens too often, or you are adjusting pressure just to maintain throughput, look at your screen. It might not be broken. Just wrong for the job.

7 Reasons Why Your Wedge Wire Screen Is Slowing Down Production

You won’t always spot the issue by looking at the screen.

But if your production has dropped and your system is working harder to push the same load, one of these reasons might be behind it.

1. Wrong Screen Design for the Application

We have seen this mistake cost sugar factories entire production days. They were using flat panel screens in a high-velocity discharge line where the slurry needed to be guided and separated quickly. The result? Overflow, blockages, and slower output.

In cases like that, a sieve bend would have done a better job. Sieve bends use gravity and flow momentum to separate solids more efficiently. They are ideal for high-flow, medium-solids processes. Flat panels have their place, but not everywhere.

2. Clogging or Blinding Due to Material Buildup

Starch particles. Sludge. Fibrous pulp. These can fill screen slots like cement if you are not careful. It does not happen all at once. First, the flow slows down. Then the pressure builds. Then the system stalls.

This happens a lot in wastewater and starch recovery plants. Especially when the screens are not inclined or self-cleaning.

You do not always need to replace the screen – sometimes, you just need the right screen orientation or cleaning setup.

Multitech Solutions:

3. Poor Slot Size or Profile Wire Selection

Slot size matters. We once reviewed a starch unit that was using 0.5 mm slots to recover fine starch slurry. It looked okay on paper. But the starch was passing right through. Recovery dropped. They lost product – and time.

Once we switched them to 0.2 mm bead mill screens, starch yield improved, and the downstream filter load dropped. You do not need tighter slots everywhere – but you need them in the right places.

4. Lack of Proper Maintenance or Cleaning Systems

Even the best screen fails if it’s not cleaned. In the paint and chemical industry, residue builds up fast. We have seen scaling in water treatment units and hardened deposits in pigment lines.

Screens do not always need replacement – they need help staying clean. That is where compactors and step screens make a difference. They automate cleaning and reduce manual shutdowns.

Multitech Add-ons:

5. Operating Under the Wrong Pressure or Flow

Screens are not universal. A screen that works at 2 bars might collapse or clog at 4 bars. Same for flow rates. We have seen systems overpressurize because the screen setup did not match the pump curve or process demand.

Using a pressure box or a properly designed header and lateral system helps control these flow characteristics and protect the screen from overwork.

Multitech Solutions:

6. Using Generic Instead of Industry-Specific Screens

One-size-fits-all is great for caps, not for industrial screening.

A second grind screen made for corn wet milling won’t work in a chemical slurry. A rotary vacuum drum filter used for pigments needs a different slot profile than one filtering sugar syrup. A germ screen must be tailored for the mix and flow conditions of that starch plant.

If you are using generic screens, you are losing performance – period.

Multitech Products Built for Specific Uses:

7. Old or Damaged Screens Still in Use

Screens wear out quietly. They do not usually snap. They wear down. Slots widen. Edges dull. The flow gets uneven. But operators do not always notice – until output dips.

We have seen pulp plants lose 10–15% efficiency just because their centrifuge baskets had not been replaced in years.

Running worn-out screens might seem cost-effective. But the downstream impact is bigger: more energy, more downtime, more rejects.

Time to Upgrade:

How Multitech Engineers Help You Fix It

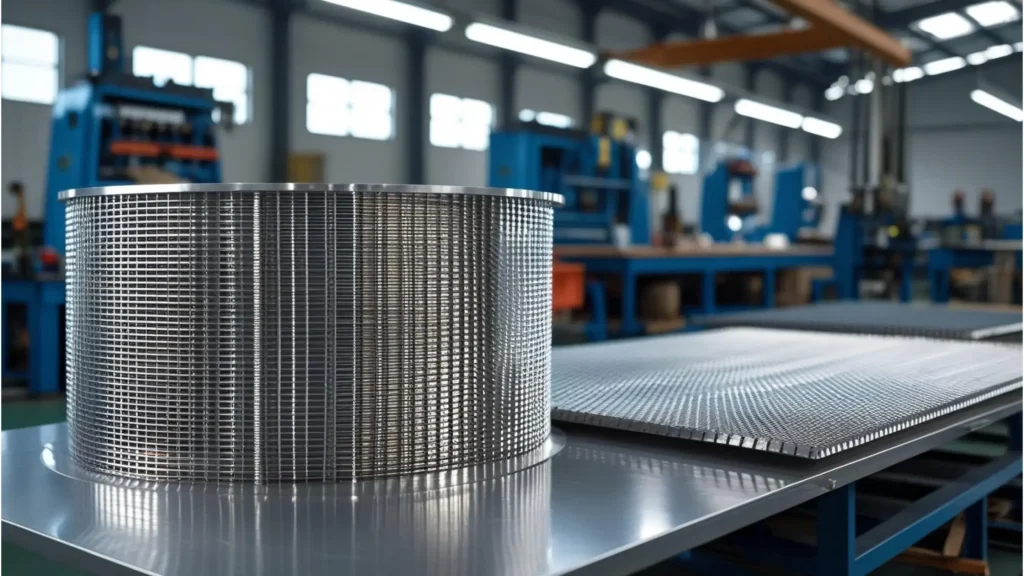

Multitech Engineers build wedge wire screening systems for people who need things to work consistently. We do not just sell screens. We design them around the job they need to do.

Whether you are separating cane fiber in a sugar mill or dealing with sludge in a wastewater tank, your screen needs to fit the material, the flow, and the pressure. That is where Multitech comes in.

We’ve worked across industries such as sugar, starch, chemical, pulp, oil & mineral processing, and water treatment. And we understand that what works for one process won’t work for another. That is why our approach is always custom.

What we offer:

- Precise slot sizing – matched to your solids, slurry, or separation needs

- Industry-specific screens – not one-size-fits-all designs

- Wear-resistant materials – because industrial systems do not run 9 to 5

- Retrofit and upgrade support – to improve existing systems without full replacement

- Consultation + after-sales service – when you are stuck, we pick up the phone

From design to installation, we make sure your screen does its job – so you can focus on yours.

Explore our products

Also read, Beyond Strength: How Our Wedge Wire Screen Handles Extreme Conditions.

When to Replace Your Wedge Wire Screen (Checklist)

Not sure if your screen is the issue? Here’s what to look for.

If you are seeing any of this:

- Reduced throughput without a clear cause

- Frequent manual cleaning or rinsing

- Material bypass – solids in the filtrate

- Unexplained pressure drops across filters

…it’s time to check your screen setup.

It might be clogged.

It might be oversized.

Or it might just be wrong for your process.

Replacing it with the right screen can bring your system back to full efficiency – without touching the rest of your setup.

Conclusion:

When your Wedge Wire Screen Is Slowing Down Production, it is not just a small problem – it affects everything. Throughput drops. Cleaning time increases. Pressure builds up. And in many plants, no one suspects the screen until it is too late.

We have seen factories lose time, product, and profit over a few millimeters of slot size – or a screen that stayed in too long.

If your production is lagging and the cause is not clear, start simple. Re-evaluate your screen.

It could be the fix you have been missing.

Need help figuring it out?

Talk to Multitech Engineers.

We will look at your process, your materials, and your current setup – and help you find a better fit.